Dewatering Solutions for the Real World

Dewatering pumps provide the best solution for removing unwanted water. Move large pools of flood water with ease.

In the real world time is money, and worksites have no time for unwanted water. AW Corp has the solutions in a complete dewatering pumps range for reliable dewatering.

Each pump type is presented with its key features, as well as dimensions, performance curves and the most important technical data for specific pump models.

Whether you work in mining, tunneling or construction, the pumps here are your best insurance against water-related downtime. From purchasing to service, you can turn to AW Corp for dewatering solutions that make a difference in the real world.

Drainage Pumps NZ

When it comes to efficient and reliable drainage solutions in New Zealand, AW Corp offers a wide range of top-quality drainage pumps. Whether you need to control floodwater, manage groundwater levels, or handle wastewater, our drainage pumps are designed to meet the demands of various applications and industries.

Our drainage pumps are built to withstand the rugged New Zealand environment, providing exceptional performance and durability. They are engineered to efficiently remove water and other liquids from different areas, including construction sites, agricultural fields, basements, and industrial facilities. With their robust construction and powerful pumping capabilities, our pumps ensure effective drainage, preventing water damage and maintaining a dry environment.

At AW Corp, we understand that each drainage project is unique, which is why we offer a diverse selection of drainage pumps to suit different requirements. Our range includes submersible pumps, dewatering pumps, centrifugal pumps, and more. We carefully source our pumps from reputable manufacturers known for their reliability and performance.

Our team of experts is available to assist you in selecting the right drainage pump for your specific needs. We take into consideration factors such as flow rate, head pressure, size of the area to be drained, and any specific challenges you may be facing. With our in-depth knowledge and experience, we can recommend the most suitable pump to ensure efficient and effective drainage.

In addition to providing high-quality drainage pumps, AW Corp also offers comprehensive support services. We can assist with pump installation, maintenance, and repairs, ensuring that your drainage system operates at its best. Our technicians are trained to diagnose and resolve any issues quickly, minimizing downtime and optimizing pump performance.

Investing in a reliable drainage pump from AW Corp gives you peace of mind knowing that you have a robust and efficient solution to manage water-related challenges. Whether it’s for residential, commercial, or industrial applications, we have the right drainage pump for you.

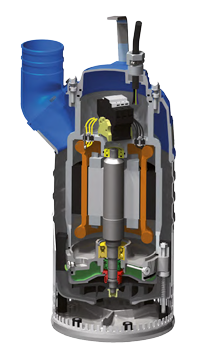

Submersible Drainage Pump Type ABS J

Submersible drainage pump type ABS J is suitable for pumping water and dirty water mixed with light abrasives. The low weight and compact design makes for convenient transport, handling and installation.

Easy start

A built-in contactor connected to the thermal sensors in the stator windings protects the motor from overheating and features an automatic restart function.

2 Wear resistance

An impeller in white cast iron with a full upper shroud and adjustable wear parts coated in nitrile rubber ensure high abrasion resistance.

3 Reliable operation

A double mechanical shaft seal in an oil bath, with primary and secondary seal surfaces in silicon carbide, extends the life of the pump. A double outer casing and good heat convection enable the pump to operate continuously at low levels – or even run dry without damaging the motor.

4 Serviceability

Due to the modular design, the same parts can be used for different pumps, which lowers the overall service costs. An adjustable diffuser ensures proper clearance throughout the impeller lifetime. By removing the top cover of the pump, the electrical junction area can easily be checked.

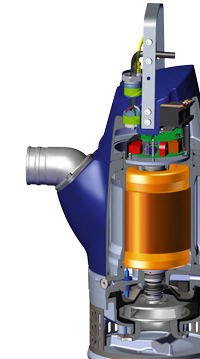

Submersible Drainage Pump Type ABS XJ

Submersible drainage pump type ABS XJ is excellent for pumping water and dirty water mixed with light abrasives. The slim design makes the pump easy to move and easy to handle.

1 Easy and fail-safe starting

Instead of a built-in contactor, an optional AquaTronic unit can be used. The AquaTronic unit compensates for incorrect phase order, which ensures correct motor rotation every time. (Additional AquaTronic functions for electronic supervision are explained on pages 16-17.)

2 Wear resistance

An impeller and wear ring in white cast iron, as well as diffusers coated in oil-resistant nitrile rubber, provide high abrasion resistance.

3 Reliable operation

Double mechanical shaft seals in an oil bath, with primary seal surfaces in silicon carbide and secondary seal surfaces in silicon carbide on carbon, extend the life of the pump. A double cable-entry seal system increases the protection against moisture entering the electrical junction area. A double outer casing and good heat convection enable the pump to operate continuously at low levels – or even run dry without damaging the motor.

4 Serviceability

Due to the modular design, the same parts can be used for different pumps, which lowers the overall service costs. The adjustable wear ring ensures proper clearance throughout the impeller lifetime. External inspection ports for the oil and motor chambers enable quick and easy evaluation of the shaft seal during service. By removing the top cover of the pump, the electrical junction area can easily be checked.

5 Less energy and environmental impact

The high-efficiency motor and new hydraulics combine with low-friction bearings to reduce power losses. The result is low total energy costs and minimized carbon footprint.

6 Flexibility

Conversion between high-volume and high-head hydraulics is managed with only a few parts, ensuring the right performance for the application.

Submersible Drainage Pump Type ABS J

Submersible drainage pump type ABS J is suitable for pumping water and dirty water mixed with light abrasives. The pump design enables convenient transport, handling and installation.

1 Easy to start

Pump J 205 has a built-in contactor connected to the thermal sensors in the stator windings, which protects the motor from overheating and features an automatic restart function. Pumps J 405 and J 604 have thermal sensors in the stator windings that protect the motor from overheating by means of an external control panel.

2 Wear resistance

Abrasive-resistant impellers, combined with diffusers and wear rings coated in oil-resistant nitrile rubber, provide extended pump life in tough applications.

3 Reliable operation

Double mechanical shaft seals in an oil bath, with primary seal surfaces in silicon carbide, extend the life of the pump. In pumps J 205 and J 405, the primary and secondary seals comprise an easy-to-replace seal cartridge. A double outer casing and good heat convection enable the pump to operate continuously at low levels – or even run dry without damaging the motor.

4 Serviceability

External inspection ports for the oil and motor chambers enable quick and easy evaluation of the shaft seal during service. By removing the top cover of the pump, the electrical junction area can easily be checked. The adjustable wear ring ensures proper clearance throughout the impeller lifetime.

5 Flexibility

Conversion between high-volume and high-head hydraulics is managed with only a few parts, ensuring the right performance for the application.

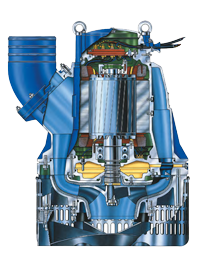

Submersible Drainage Center-Line Pump Types ABS JC and XJC

Submersible drainage center-line pump types ABS JC and XJC are excellent for pumping water and dirty water mixed with light abrasives. The slim design makes them easy to move and easy to handle, and they are perfect for applications with limited installation space.

1 Easy and fail-safe starting

In XJC pump models, an optional AquaTronic unit can be used instead of a built-in contactor. The AquaTronic unit compensates for incorrect phase order, which ensures correct motor rotation every time. (Additional AquaTronic functions for electronic supervision are explained on pages 16-17.) In JC pump models, a built-in contactor with an automatic restart function protects the motor.

2 Wear resistance

An impeller and wear ring in white cast iron, as well as diffusers coated in oil-resistant nitrile rubber, provide high abrasion resistance.

3 Reliable operation

Double mechanical shaft seals in an oil bath, with primary seal surfaces in silicon carbide and secondary seal surfaces in silicon carbide on carbon, extend the life of the pump. Pumps XJC 50 and XJC 80 have a double cable-entry seal system that increases the protection against moisture entering the electrical junction area. A double outer casing and good heat convection enable the pump to operate continuously at low levels – or even run dry without damaging the motor.

4 Serviceability

Due to the modular design, the same parts can be used for different pumps, which lowers the overall service costs. The adjustable wear ring ensures proper clearance throughout the impeller lifetime. External inspection ports for the oil and motor chambers enable quick and easy evaluation of the shaft seal during service. By removing the top cover of the pump, the electrical junction area can easily be checked.

5 Less energy and environmental impact

Pumps XJC 50 and XJC 80 are equipped with high-efficiency motors and new hydraulics, which combine with low-friction bearings to reduce power losses. The result is low total energy costs and minimized carbon footprint.

6 Flexibility

Pumps XJC 50 and XJC 80 allow conversion between high-volume and high-head hydraulics with only a few parts, ensuring the right performance for the application.

Contact Us For Information about our range of Dewatering Pumps.